This is defined as a wind direction within an arc of 90 degrees with the wind blowing from source to receiver. Below are suitable conditions taken from ISO9613-2. Sound propagation is affected by variations in meteorological conditions. not floating above the ground or with empty sections / perforations. Screens are flat with no significant transmission of sound through or under the screen.The ground is of a continuous type (a single ground factor).Noise sources behave as a point (or line for line sources) and are far-field, where inherent directivity is minimal.With our fully portable ultrasonic testing systems, our technicians can mobilize to any location and perform UT examinations with uncompromising accuracy. This equipment is portable and can be used in remote locations. This ensures complete coverage of the material being examined.

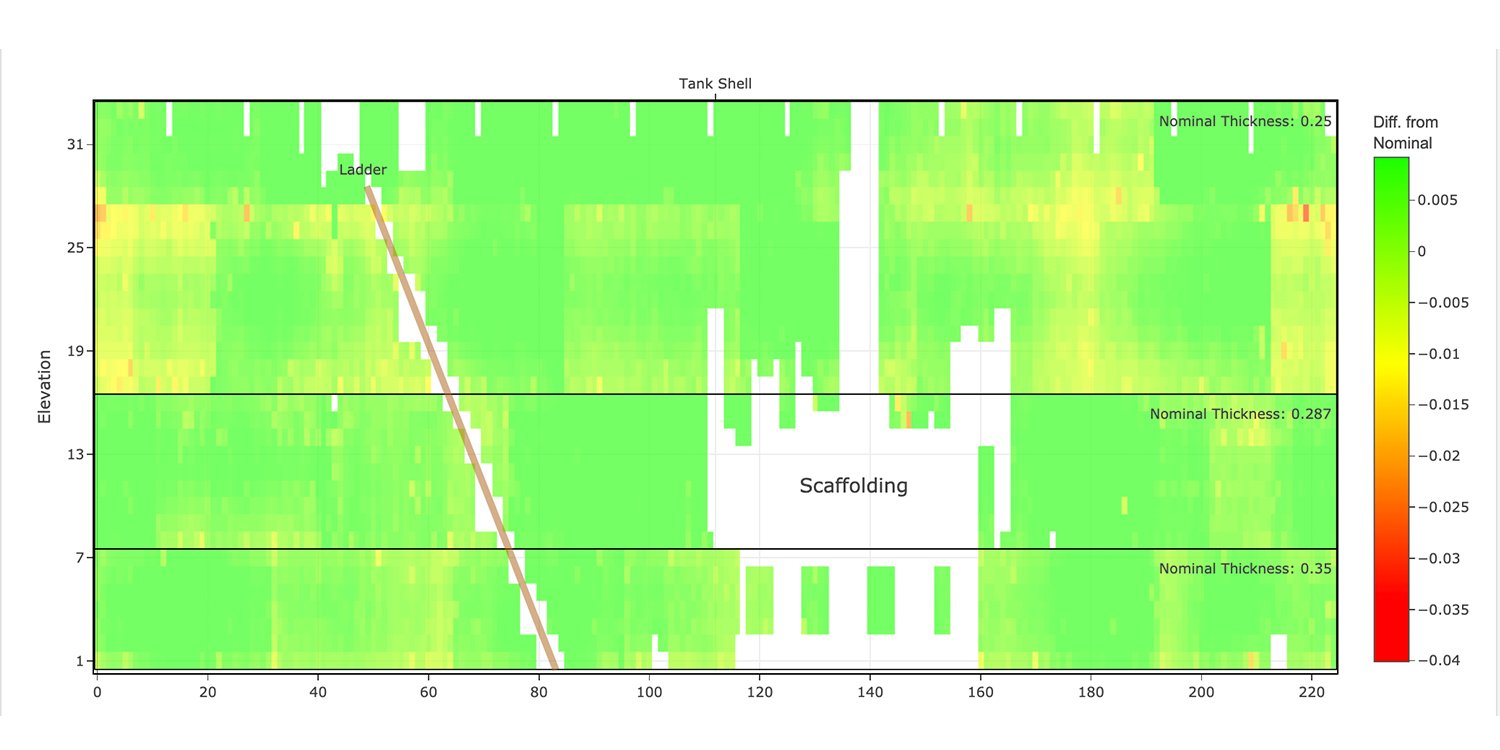

umbilical) due to a highly adjustable chassis and strong magnetic wheels, which allow thickness data to be collected every 0.30” and at speeds up to 30” per second.

Automated corrosion mapping can be used on 2” diameter piping up to flat plate (vertical climb with 100ft. The data collected can be analyzed in various formats to include 3D images and calculations, as well as characterizations of damage and discontinuities. Shawcor’s automated ultrasonic testing systems can be used to obtain vast amounts of data in fast progression. Asset owners can use the data provided by ultrasonic testing to assess and create integrity management plans.ĪDVANCED TECHNOLOGY USING AUTOMATED CORROSION SCAN MAPPING Manual ultrasonic testing techniques utilize highly portable equipment that can be used in many situations and industries. By analyzing these sounds waves, it is possible to measure the thickness of an item, or potentially find evidence of flaws and discontinuities, while discounting reflections from normal (geometric) indications.

These high frequency sound waves are directional, and travel through materials such as steel until they encounter a boundary with another medium, at which point they reflect back to the transducer. Ultrasonic Testing uses high frequency sound waves to measure the thickness or internal structure of a test item. Collecting full volumetric measurements on various materials by using manual or automated equipment with Non-Destructive and Ultrasonic Testing methods.Įxperienced technicians at Shawcor use Ultrasonic Testing (UT) to collect thickness data and determine if any anomalies are present on various materials to ensure operators’ code compliance, as well as data collection for preventative maintenance, planning and risk assessment.

0 kommentar(er)

0 kommentar(er)